Jiushengfa Company leverages twenty years of industry experience to establish a rigorous product selection and quality control system, ensuring the durability and compatibility of sealing components. Specializing in oil seals and hydraulic fittings for construction machinery such as excavators and loaders, we provide a full range of high-quality sealing solutions. Moving forward, we will continue to focus on technological innovation and customer needs, striving to become a benchmark enterprise in the engineering machinery parts sector. Our goal is to deliver more efficient and reliable sealing and hydraulic solutions for the industry.

Whether your project is large or small, Shangping can supply standard products or custom fabricate to your requirements with industry leading production times.

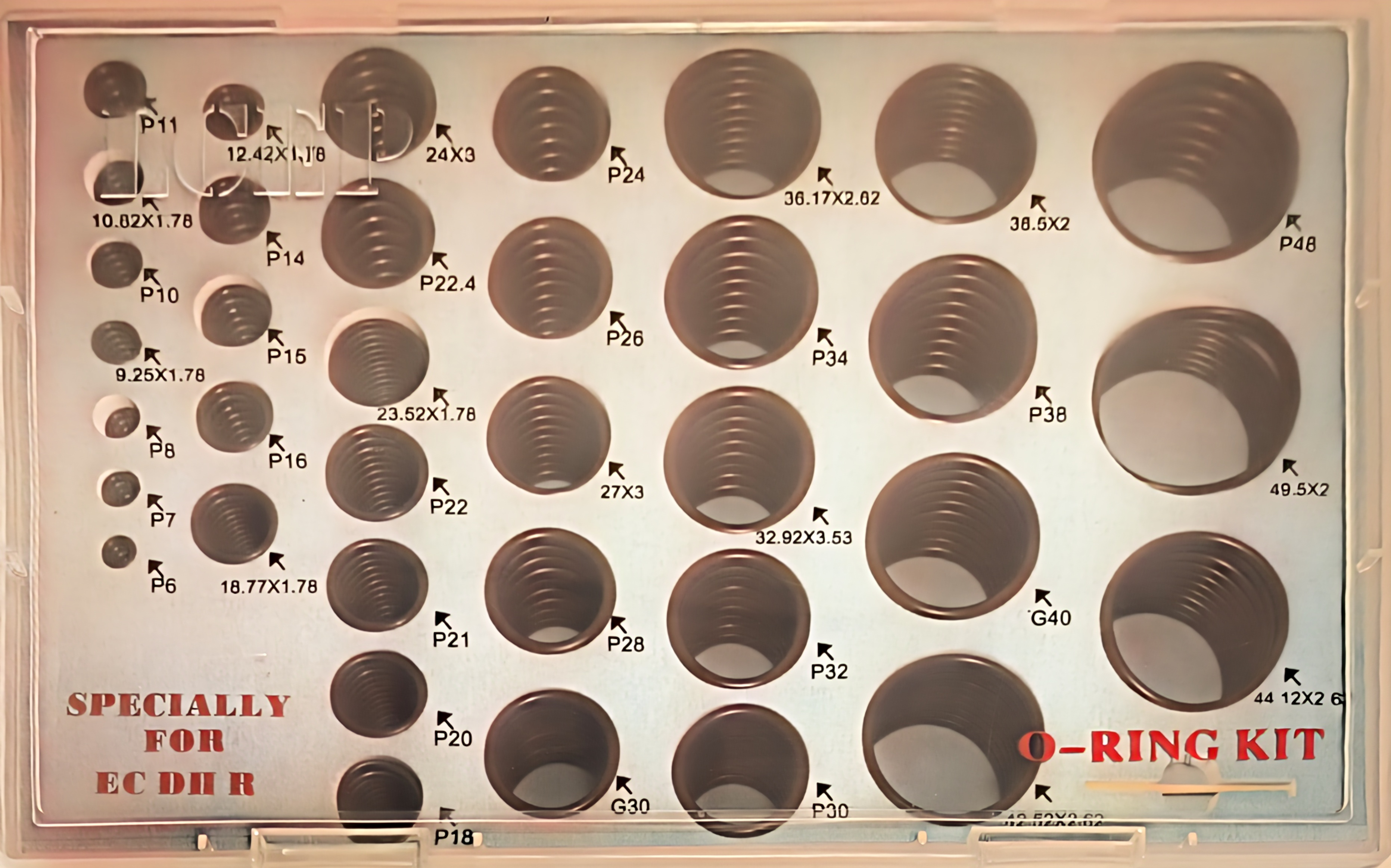

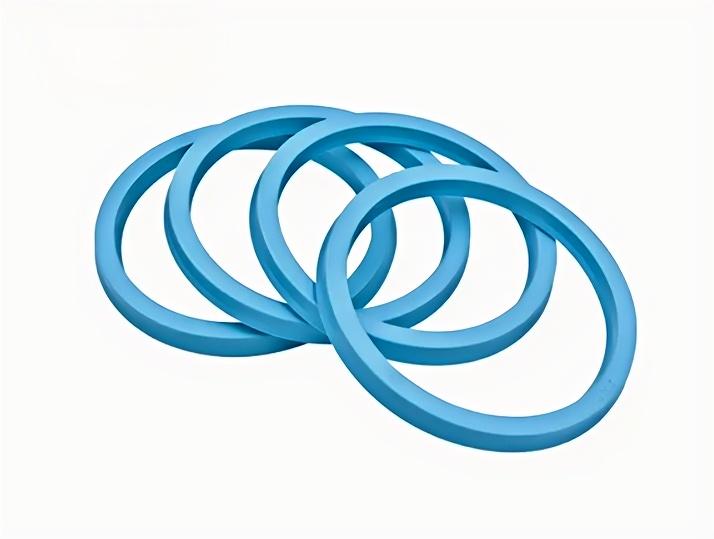

Various optional materials: NBR FKM EPDM rubber O-ring oil seal, nitrile rubber seal O-ring high temperature resistant hydraulic cylinder seal

READ MORE

Various optional materials: NBR FKM EPDM rubber O-ring oil seal, nitrile rubber seal O-ring high temperature resistant hydraulic cylinder seal

READ MOREOUR PRODUCTS

WHAT WE PROVIDE FOR YOU

Professional Team Support, Excellent Reputation & Customer Trust Personalized Service: Tailored solutions designed for your specific needs to ensure the perfect match. Competitive Pricing: Delivering greater value and higher returns for your investment.

Clarify quality requirements: Based on industry standards and customer needs, conduct real-time monitoring of production or service processes to ensure each step complies with standards. Through systematic quality control, enterprises can consistently deliver high-quality outcomes and maintain a competitive edge.

Jiushengfa Mechanical will continue to prioritize technological innovation and customer needs, striving to become a benchmark enterprise in the engineering machinery components sector, providing more efficient and reliable sealing and hydraulic solutions for the industry.

OUR CASE

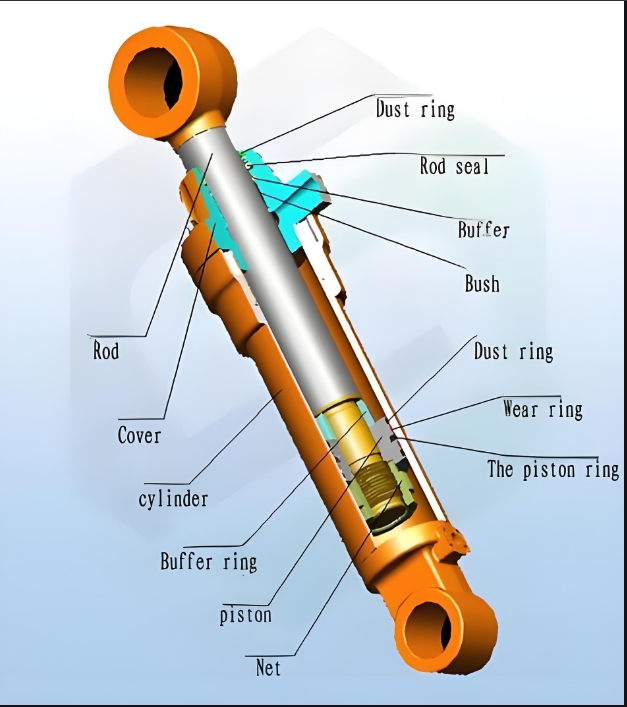

Ensure the oil seal is installed correctly through the following ten aspects to extend the service life of the oil seal:Cleanliness,Lubrication,Correct Orientation,Avoid Damage,Proper Tools,Alignment,...

Ensure the oil seal is installed correctly through the following ten aspects to extend the service life of the oil seal:Cleanliness,Lubrication,Correct Orientation,Avoid Damage,Proper Tools,Alignment,...

Ensure the oil seal is installed correctly through the following ten aspects to extend the service life of the oil seal:Cleanliness,Lubrication,Correct Orientation,Avoid Damage,Proper Tools,Alignment,...

Trustworthy

We are a trading company with nearly 20 years of industry experience..

Product packaging plays a vital role in the entire order process

Optimization of hydraulic seal material and service life...

We chat